Learn more about Henkel Brands & Businesses in UK & Irelands: Includes useful information about the brands, technologies and latest innovations in our business areas: Adhesive Technologies and Consumer Brands.

Everyone is talking about it: the circular economy. Packaging materials like plastic have many advantages, but their omnipresence has created a new set of challenges for us. How can we promote a responsible use of plastic within a circular economy and combat the problem of plastic waste through recycling?

Recycling, reusing, reducing – closing the loop

Plastic is the standard material for a huge number of applications. For example, plastic is often used for packaging because it’s able to fulfill an impressive range of functions – from making sure products stay undamaged while being transported and used, through to providing the right amount of product whenever it is needed. Since plastic packaging weighs less than other alternatives, it can even reduce the carbon footprint created during transport. This means that plastic is not bad in and of itself – it is a valuable material. The problem comes from the way in which plastic is used, and that is where the concept of a circular economy comes into play.

The most effective way to address plastic’s impact on our planet is to transform our modern way of life and adopt a system in which all materials used can either be reused or repeatedly recycled. This solution – known as the circular economy – would cut waste, decrease resource consumption and reduce environmental pollution.

Circular economy along the value chain

Explore how we drive progress toward a circular economy along the value chain:

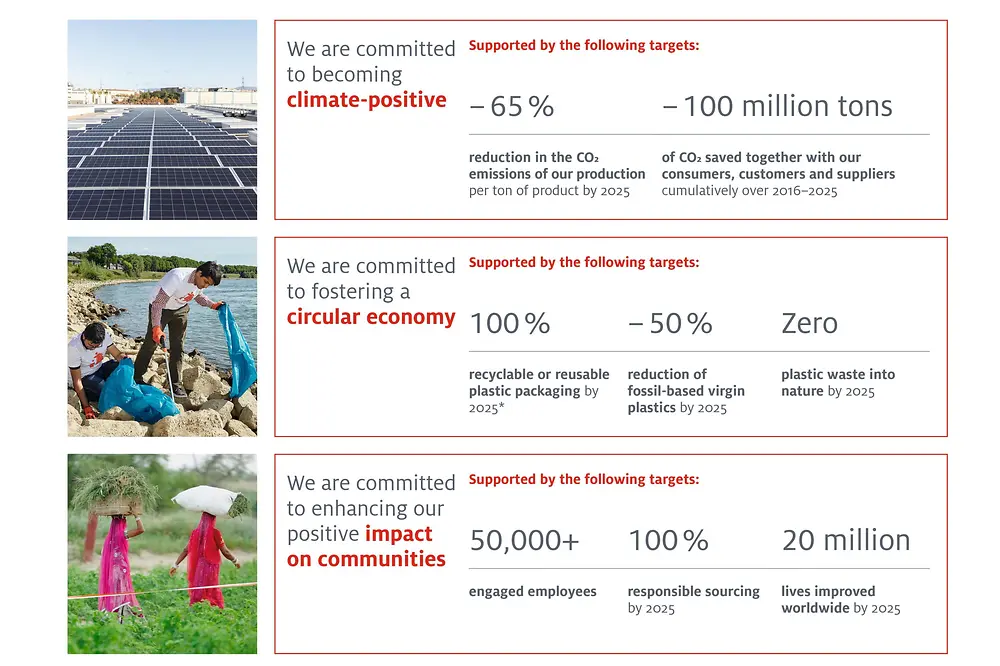

Our packaging mission: Strong focus, ambitious targets

Plastic is not the enemy. It‘s rather about the right handling with this valuable material. It is important to keep plastic in the loop as long as possible and to rethink our packaging design in every possible dimension.

Thorsten Leopold, Director Global Packaging Innovation, Laundry & Home Care at Henkel

How adhesives are accelerating the transition to a circular economy

Circularity goes far beyond consumer plastic: It is about completely transforming the way we think about resources, and turning waste into a valuable raw material. Single-use plastic straws, for example, are gaining a lot of attention and are the focus of increasingly strict legislation. Our adhesives are enabling the switch to paper straws as a more sustainable alternative. Industry standard paper straws are made of three layers of paper with a thin layer of our adhesive between each layer. Our technology makes it possible for paper straws to withstand immersion in liquid for a longer period of time, and tests have confirmed that the paper straw packaging is biodegradable, which contributes to circularity by eliminating waste.

Our circular economy stories

Learn more about sustainable packaging and circular economy and deepdive into our stories and guest articles from experts around the world:

The power of partnerships: together reducing our environmental footprint

Henkel is actively engaged in several partnerships aiming to drive progress toward a circular economy:

Circular economy FAQ

What is a circular economy?

Our understanding of a circular economy goes along with the definition of our partner the Ellen MacArthur Foundation: A circular economy is a systemic approach to economic development designed to benefit businesses, society, and the environment. In contrast to the 'take-make-waste' linear model, a circular economy is regenerative by design and aims to gradually decouple growth from the consumption of finite resources.

What is mechanical recycling?

Mechanical recycling of plastics is the most common form of reprocessing. It occurs by melting, filtering and degassing in an extruder. Used parts are shredded, cleaned and sorted by type. When items are very compatible and recycling streams are very pure, it is possible to recycle in a closed loop – this exists for example for PET bottles, which can be made out of 100% recycled plastic. More common is open loop recycling which accepts certain incompatibility and conta-mination.

What means chemical recycling?

Chemical recycling is a general term used to describe innovative technologies where post-consumer plastic waste is converted into valuable raw materials, to be used as feedstock by the chemical industry. It gives the possibility of removing pollutants and the potential of using waste that is difficult to recycle or heavily contaminated.

What are the benefits of bio-based plastic?

Bio-based plastic it enables more sustainable solutions. Provided they can deliver the same technical performance as conventional polymers, they could offer a good alternative and provide long-term benefits. Henkel explicitly exclude sources of raw materials that might be in competition with food. For this reason, we are testing the use of second-generation bio-based feedstock material.

Which role plays packaging in a circular economy?

Well thought-out packaging design plays a central role in the circular economy, especially when it comes to replacing new materials with recycled alternatives. With concepts that work with more sustainable materials in smaller quantities, we can significantly reduce waste and its negative impact on the environment. To transform a linear economy into a circular one, packaging concepts need to be rethought to allow materials to be preserved throughout economic cycles.